The production line of Vatan Gostardeh Iranian company is capable of producing all kinds of industrial stretch film (polyethylene) without limitation in dimensions and high quantity. Other specifications of industrial stretch films produced in our factory are as follows.

Industrial stretch film production process

Considering that the stretch film has a small thickness and the low strength of raw materials, it is not possible to use grade 2 or grade 3 raw materials for the production of these products, and petrochemical grade 1 materials must be used.

In general, 97% of polyethylene raw materials (LDPE) and 3% of glue are used for the production of industrial stretch films. Stretch films are produced by injection (casting or molding) and blowing. The only important factor that determines the quality of the final product is the type of machine used in the production of stretch films.

The combination of the mentioned raw materials is the routine of the production line of the Vatan Gostardeh Iranian company. It is also possible to produce stretch pallet film with the specifications and special combination of raw materials in a customized and unlimited manner according to the needs of the industrial owners. For example, by increasing the amount of glue in the initial composition, the possibility of stretch adhesion increases, or by adding metallization, its strength and elasticity increases.

Dimensions and thickness of the packaging stretch film

As we said before, Vatan Gostardeh factory is capable of producing industrial stretch films in different sizes and thicknesses according to the customer’s needs. The general specifications of stretch industrial films are as follows.

- Weight: The weight of stretch roll packaging can be produced from 1 kg to 50 kg according to the customer’s order. Of course, the larger the roll, the more difficult it will be to use for packaging.

- Thickness: Normally, this product is produced from 12 microns to 35 microns thick.

- Stretch plastic width: 25 cm, 38 cm and 50 cm

- Elasticity: 600% (Stretch is stretched up to 6 meters.)

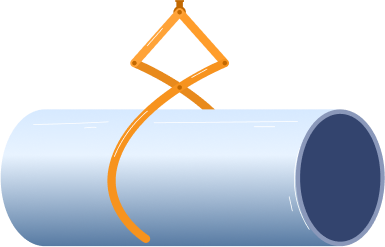

Various methods of using stretch pallets

Stretch wrapping of products is done in two ways as follows:

- Manual stretch pallet: In this method, human power and manual stretching tools are used to pack the products.

- Using the stretch device: In this method, which is done without human intervention, according to the volume and dimensions of the product packaging, there are different devices that do this automatically.

Buy stretch wrapping film

When buying, the quality and stretch film price is the most important factor that you should pay attention to, because buying quality stretch film has a great impact on product packaging and will lead to customer satisfaction.

Another important factor to consider when buying is its elasticity. Stretch films should be at least 300% elastic so that, in addition to being economical in using nylon, they do not tear during packaging and handling. If the elasticity of the stretch film is not high, due to the slightest pressure or impact, it will tear at one point and the product must be repackaged. If this happens several times, it will waste a lot of stretch and it will not be economical for customers.

Another point that you should consider when buying is the degree of stretch adhesion, which should have a balanced adhesion, so that after being stretched, it does not loosen and maintains the shape of the product packaging. Also, when moving the product, it does not change its shape and sticks around the packaging.